Search This Supplers Products:Single Point Load Cellsshearbeam load cellS type load celldouble ended beamcolumn load cellSpoke Type Load Cell

Digital Load Cell and Its Characteristics

publisherVikki Chen

time2018/01/23

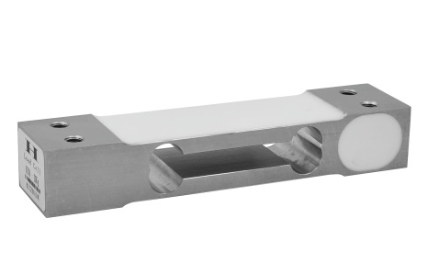

Based on the traditional resistance strain load cell, and combined with modern microelectronics technology and microcomputer technology integration, digital load cell system is a new type of electronic weighing technology. It is composed of two parts: analog load cell (resistance strain type) and digital conversion module.

Digital modules are made of highly integrated electronic circuits using SMT surface mount technology including amplifiers, A / D converters, CPUs, memory, interface circuits (RS485) and digital temperature load cells etc. It has the following features:

1, Digital load cell uses integrated A / D converter circuit, digitalized signal transmission and digital filtering technology.The analogy signal is soon transfered into digital signal inside the digital load cell, because of the short transmission distance and shield function by the cover of load cell, the anti-interference function is excellent, largely improved the stability of load cell. Besides, the signal of digital load cell can be far up to 1,200 m.

2, Digital load cells have anti-cheating function, can effectively prevent remote control cheating. Once detecting remote-control, it will automatically operate the error alarm, effectively protect the security and accuracy of data. Since the cheater is small and easy to install, the truck scale with analog is easy to be installed on and hard to find, which causes big problems for security of data. Digitalization of analog load cell can largely improve the safety of data, which brings benefits for company .

3,Since the digital load cell have pretreatment, storage and memory function, when using many digital load cells in one equipment, technician can check the status of each load cell, which makes it easy to check the problem when something is wrong with it. While when using an analogy load cell, all the load cells are jointed together and send an overall mV signal to the equipment. If the working status for the equipment is not good, it will be hard to find out the problem one, the technician will have to open the junction box and test each one, which will cost a lot of time and money. This case fully proved the superiority of the digital load cell and its importance in the actual production.